Home / Production

Production

Manufacturing

Our manufacturing of electronic boards and complete products adheres to IPS-A600, IPC-A610, IPC-6012, J-STD-033, J-STD-020, ISO 9001, UL standards, ensuring that each piece you receive is a model of reliability and performance.

Production is a complex and precise process respecting the technical data. This process involves all or part of these services:

- Creation of manufacturing orders

- SMD

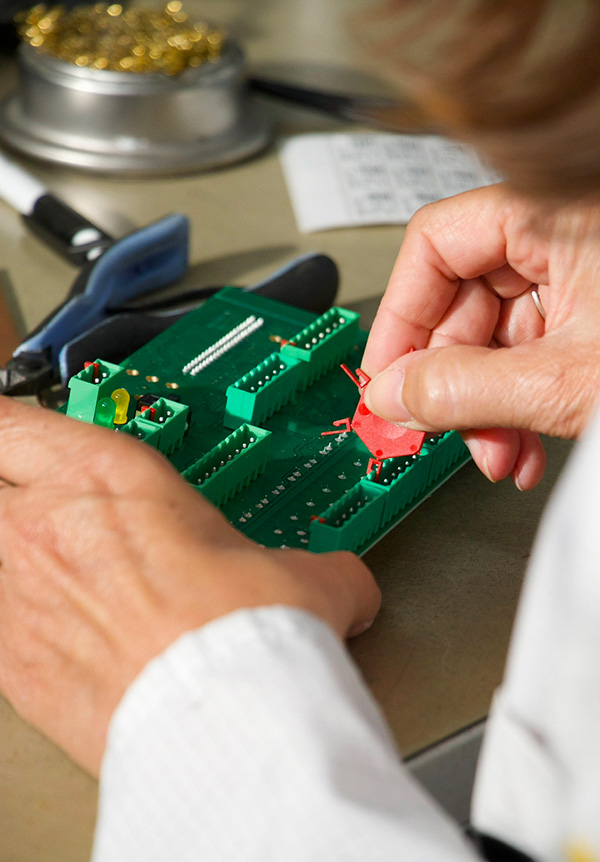

- Manual insertion

- Selective wave / traditional wave

- Varnishing

- Testing

- Packaging

- Logistics management

We use state-of-the-art machines and lead-free soldering techniques to guarantee precise and reliable production.

Our productions are mostly carried out at the BSE Electronic site in LE CREUSOT (France). For certain client requests, depending on the product type, BSE can offer high-quality solutions through its Tunisian electronic partners.

Testing

The testing phase is the quality guarantee that ensures our products meet your strictest requirements, guaranteeing your satisfaction.

The testing phase consists of:

Our team ensures:

- Compliance with specifications

- Tolerance measurements

- Functional tests

- Durability/reliability assessment

- The absence of quality defects during the manufacturing process

Electronic board and/or finished product testing is a crucial step in developing and producing electronic devices. They guarantee that the electronic components are functional, minimizing the risk of subsequent failure and contributing to the overall quality of the electronic product.

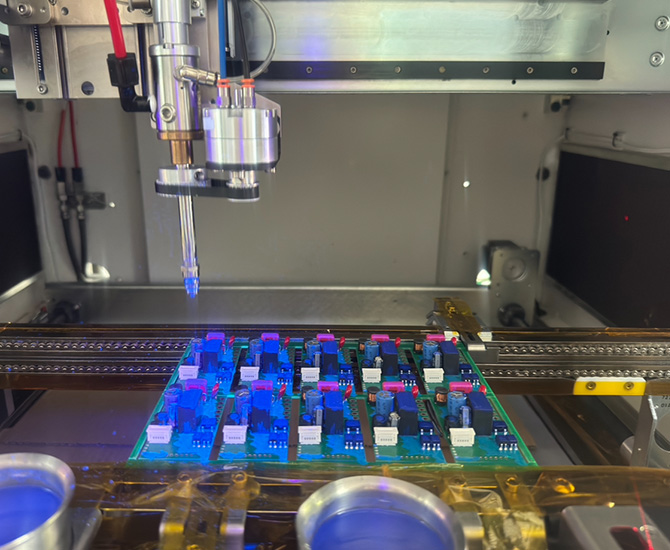

Tropicalization

Protect your electronic boards from moisture, thermal shocks, and corrosion with our varnishing expertise, ensuring exceptional performance even in the harshest environments.

This process involves applying special coatings, such as varnishes or protective treatments, on electronic boards. Tropicalization aims to:

- Extend the lifespan of electronic devices

- Reduce the risk of malfunctions due to environmental factors

- Ensure reliability in harsh environments

For sought-after sealing, BSE can also provide card potting services.